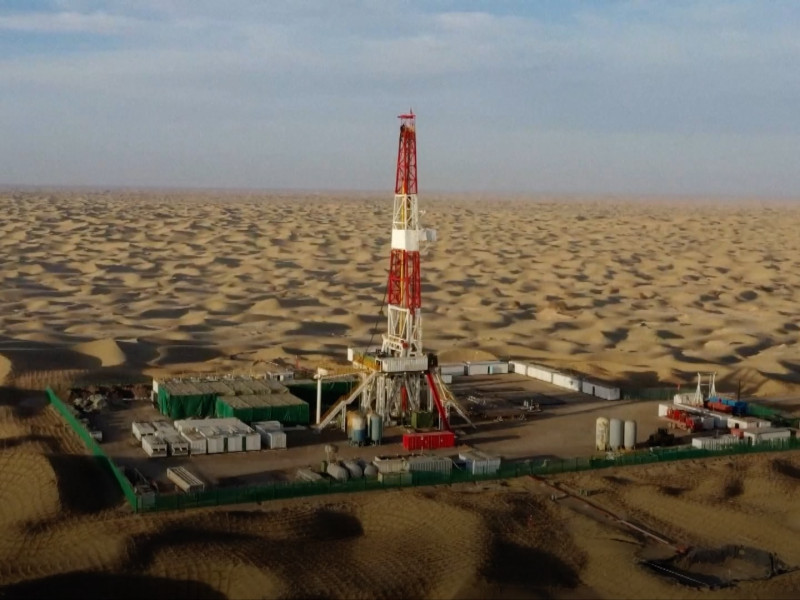

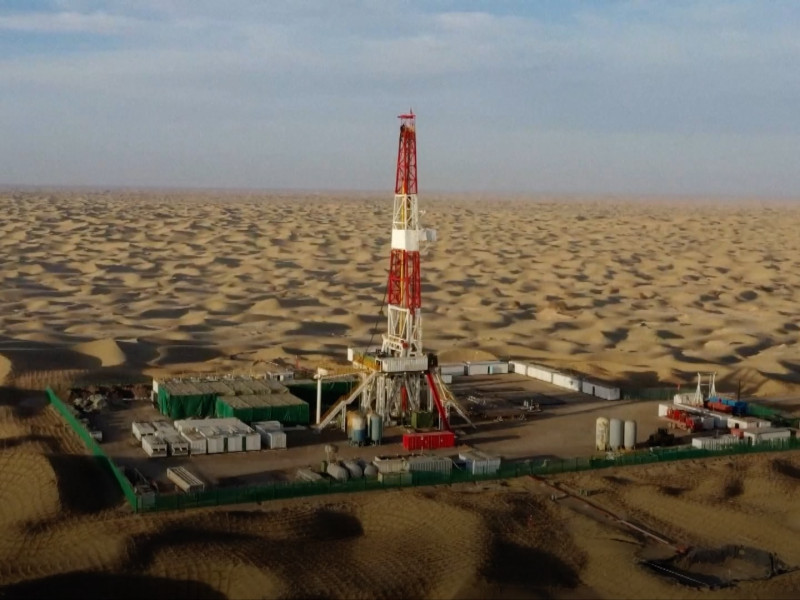

The Importance of Drilling Jack Upkeep

An essential part of drilling operations are drilling jacks. They provide stability and support for the drill string's weight when drilling. Drilling jack maintenance issues can result in expensive downtime and significant safety hazards.

Prior to Maintenance Examination

It's imperative to start with a comprehensive pre-maintenance examination before starting any maintenance. This entails closely inspecting the drilling jack to look for any signs of wear. We advise paying special attention to hydraulic hoses, fittings, and seals when performing these inspections. Furthermore, it's critical to look for any hydraulic fluid leaks, as these might impair both performance and safety. Finally, check for any possible problems, such loose parts or misalignment. The basis for preserving equipment performance and safety is laid by this inspection.

Tasks for Regular Maintenance

Regular maintenance is necessary to ensure the proper operation of your drilling jacks. This entails lubricating moving components to lower friction and increase equipment lifespan. In order to avoid contamination and damage, keep the drilling jack clean by clearing away any dirt, debris, and extra grease. Additionally, ensure that the drilling jack performs within its prescribed parameters by making the appropriate modifications to maintain optimum alignment. These regular upkeep duties are necessary for durability and optimum performance.

Safety Procedures

When using drilling jacks, safety should come first. To protect oneself from potential threats, wear the necessary personal protection equipment, such as steel-toed boots, gloves, and safety glasses. When doing maintenance on the jacks, use lockout/tagout protocols to avoid inadvertent activation. Additionally, keep in mind to keep a safe distance from the drilling jack while it is in use and make sure that no one is in contact with the machinery. These security procedures are essential for a safe workplace.

Common Problems with Maintenance

Common problems that arise during maintenance include worn-out parts or hydraulic leakage. In order to fix these problems, locate the source of any hydraulic leaks and replace any hoses or seals that are damaged right away. Make sure to swap out any worn or damaged parts when working with worn components. This preventative measure is crucial to keeping your drilling jack dependable and effective.

SPT

Just now

SPT

Just now