We’re going to dive deep into the world of drill string, specifically, the world of drillships. Because the drill string is at the heart of every drilling operation, choosing the right one can make a world of difference. So, let’s take a look at what drill string options are and what to consider when choosing the right one for your drillship.

Knowing How to Read Drill Ship Drill Strings

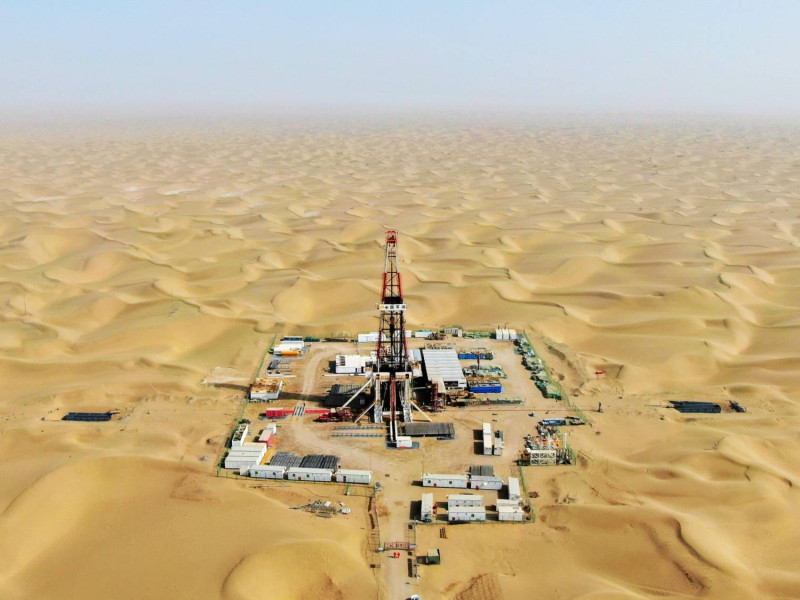

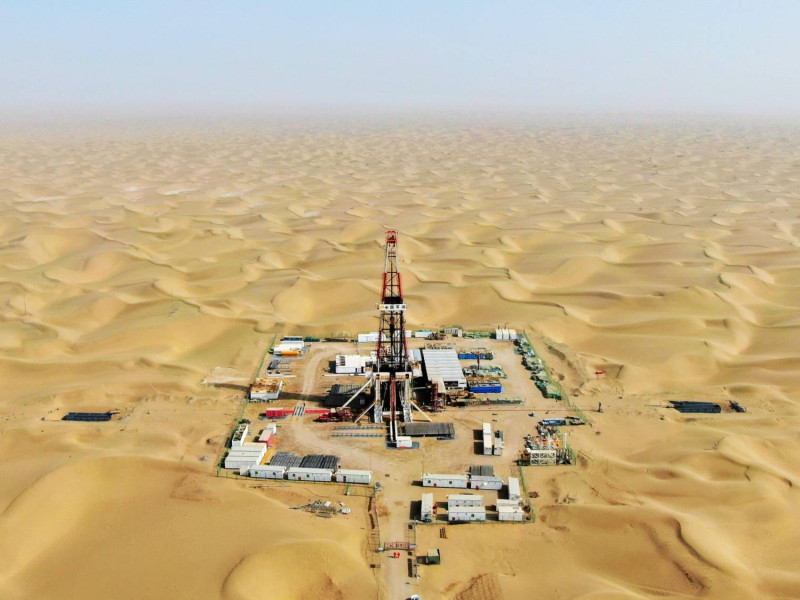

It's important to comprehend the importance of drill strings in offshore drilling, especially on drill ships, before we get into the many types of drill strings. A drillship is a type of floating vessel used to produce oil and gas from the ocean floor by drilling deep down. The drill bit and the drilling rig are connected by drill strings, which are essential for the movement of fluid, weight, and torque. They are the operation's workhorses.

Drill Ship Types of Drill Strings

Drill strings come in a variety of forms, but for drill ships, we'll concentrate on the two main varieties: spiral and slick.

Drill Strings That Are Smooth

One distinguishing feature of slick drill strings is their seamless, jointless design. Their effectiveness and simplicity make them popular. Slick drill strings have the benefits of less drag, less torque needed to drill, and better hydraulics. Because of these advantages, slick drill strings are a great option for less difficult drilling circumstances, increasing drilling efficiency and reducing costs.

Drill strings come in a variety of forms, but for drill ships, we'll concentrate on the two main varieties: spiral and slick.

Slick drill strings are less robust and may wear down more quickly, thus they might not be the greatest choice for really abrasive formations. They may also provide less traction due to their flat surface, which makes them less appropriate for steeply inclined wells.

Drill Strings in Spiral

In contrast, spiral drill strings have a helical groove along the length of them, which increases their grip on the wellbore. For deepwater and extended-reach wells, this design increases stability and lowers the chance of sticking when drilling through difficult rocks. These products enhance the drilling operation overall by providing lower pipe vibration and efficient weight transmission.

When drilling at severe depths and angles, or in the presence of abrasive formations, spiral drill strings are a great choice for your drill ship. They improve output and safety.

Safety and Upkeep of Drill Strings

Maintenance and safety are of the utmost importance, regardless of the type of drill string you select. Maintaining the longevity and peak performance of your rig requires routine inspections and appropriate care. If you are worried about the condition of your setup, get advice from a drill string maintenance specialist.

SPT

Just now

SPT

Just now